It is no secret that if you want to take your vehicle's handling to a higher level of performance, you have to upgrade its key suspension components. Most everyone automatically thinks that changing springs and shocks is the answer for ultimate handling, but one often overlooked and critical components are your vehicle's swaybars. While the stock swaybars on most vehicles are fine for everyday driving conditions, performance/spirited driving, or driving on a race track or gymkhana course requires a much higher level of swaybar performance if you want to maximize your vehicles road holding and your overall driving experience. From a safety perspective, stock swaybars can fail when pushed over their limits, exposing you and your vehicle to potentially dangerous and uncontrolled driving conditions. As part of our continuing documentaries on performance parts, in the ensuing paragraphs, we will define how a swaybar performs, and expose the major differences in swaybars that you need to be aware of before you purchase this easy to install upgrade.

Background Swaybars (aka: anti-roll bars, stabilizer bars, stay-bars) are a critical part of a vehicles suspension system that helps reduce the body roll of a vehicle during fast cornering or over road irregularities. It connects opposite wheels together (left side / right side) through lever arms linked usually by a tubular structure that functions as a torsion spring, leveraging cornering forces to assist maintaining the vehicle level during turns. A swaybar increases the overall suspension's roll stiffness - that is its resistance of your vehicle to roll in turns during normal and aggressive driving conditions. Note that roll stiffness is different and independent of the vertical movements that your suspension springs provide - however both need to work in complete harmony together so as to maximize your vehicle's drivability, safety, and performance characteristics. A swaybar is made from a specially constructed and bent U-shaped piece of steel that connects to the vehicle's body at two key mounting points, and then is also connected to the appropriate left and right hand portions of the lower suspension member. If the left and right wheels move together, the bar just rotates about it's mounting points and does not bend. If the wheels movement is not relative to each other, the bar is subjected to torsion and is forced to twist. It is this twisting motion that the bar resists through its stiffness and acts to reduce the amount of lean by the vehicle.

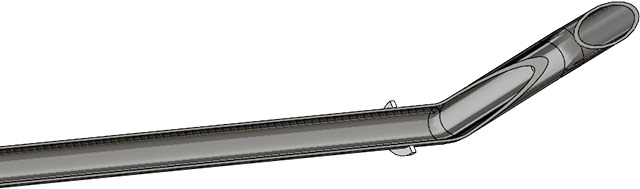

[caption id="attachment_2550" align="aligncenter" width="640" caption="Steeda's 2005 & Newer Mustang Front

Swaybar"] [/caption]

[/caption]

Many factors affect how a sway bar performs, including:

- The specific metal selected for the swaybar (type and composition of steel, it's thickness, etc).

- The inverse of the length of the lever arms (i.e., the shorter the lever arm, the stiffer the bar)

- The geometry of the mounting points

- The swaybar's mounting and isolation points

Aggressive street and racing sway bars provide for individual adjustment of the lever arms, allowing the stiffness of the swaybar assembly to be modified by adjustments that increase or reduce the length of the lever arms. This adjustment permits the roll stiffness to be tuned for different race or competition situations without replacing the entire bar. The stiffer the bar, the more force required to move the left and right wheels relative to each other. The end result is that this increases the amount of force required to make the body roll and the force that was going to be used for body roll is now being placed on the tire that needs traction.

What are the primary differences in Swaybars? Not all swaybars available in the market today are the same - as there are many different ways to construct a swaybar, different materials that may be used, and different ways to engineer a swaybar. As a matter of fact there are even some aftermarket swaybars that can dramatically cause a negative affect on your vehicle's handling or not deliver the desired outcome you desire... so it is important that you make an informed decision before purchasing any swaybar for your vehicle. Following is a discussion that identifies some of the key differences that you need to be aware of:

Solid vs Tubular Bar Construction

Most swaybars supplied on vehicles today and available in the aftermarket are made from heavy solid steel bar stock. To the novice, the thought of a solid bar has the implication of strength and superior construction due to it's sheer mass, however there are many misconceptions and major disadvantages to solid bar stock that you need to be aware of before you consider a bar of this type. One of the primary deficiencies of solid bar construction is the overall weight of the bar and the effect it has on your cars un-sprung mass. Suspension designers and racers alike, all strive to reduce the un-sprung mass as much as possible so that maximum performance can be obtained.

[caption id="attachment_2548" align="aligncenter" width="640" caption="Steeda's Hollow Swaybars Help Reduce Unsprung

Weight"] [/caption]

[/caption]

Remember: Weight is the enemy of performance, and a solid bar easily outweighs one of our comparable tubular bars by a substantial margin - sometimes as much as 65%. At Steeda, we strategically design and engineer our swaybars from tubular stock using a far superior and proprietary alloy of our own specifications. This alloy provides exceptional yield strengths that are substantially within any foreseen/projected failure points, ensuring that it will never fail under the most sever street or race conditions you could ever subject it to. And the lighter weight of our tubular bar dramatically reduces un-sprung weight - further enhancing your vehicles performance. After all of the computer analysis and simulations our engineers perform, we then bolt the swaybar into one of our test vehicles and then torture test it on some of the most harsh race conditions possible at some of the harshest tracks - all in an effort to guarantee the very best swaybar possible for you.

Swaybar Ends

Most swaybars available today are made from a solid round bar whose ends are coined or smashed flat and punched for mounting holes. The drastic change to the cold-formed material during the "smashing process" creates many small microscopic stress fractures. Experienced metallurgists will tell you that whenever you do that, you effectively destroy the structural integrity of the material thereby creating a potentially weaker / stress spot for a potential future point of failure. The Steeda solution: Steeda Autosport's Swaybars are designed and made in the USA in our facility under strict ISO 9001-2008 quality control process using the very best materials available - we take absolutely no shortcuts when it comes to the quality level of manufacturing we utilize.

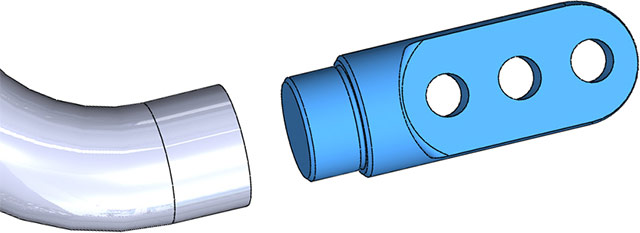

[caption id="attachment_2534" align="aligncenter" width="640" caption="Steeda Billet Swaybar Ends"] [/caption]

[/caption]

Rather than taking a shortcut and smashing the ends of the bar, our swaybar ends are precision machined out of an exceptionally strong proprietary material and then are mated to the tubular bar with a weld joint that structurally bonds the two parts together at the molecular level. When joined together, the welded joint is actually the strongest part of the bar - stronger than a solid or tubular bar. The end result is the portion of the bar that has the greatest level of stress is actually the strongest part of the bar - ensuring that it will not fail no matter the forces and stress you may subject it to.

Manufacturing Process

Most swaybars manufactured by aftermarket companies are made from heavy, solid steel stock and are bent on a tubing bender. Oftentimes the material they choose for the bar is dictated by the type of bending machine they utilize for the manufacturing process - this is not the way you want your swaybars manufactured! Some manufacturers may use a more costly mandrel bender for their manufacturing process, but they lack the overall Computer Aided Manufacturing process that would ensure a consistent level of manufacturing that are certified by ISO.

At Steeda, we take suspension systems very seriously, and we invested an insane amount of capital in developing a swaybar manufacturing machine to our own unique specifications. Creation of this machine incorporated the most advanced and most costly computer controlled manufacturing processes and a hydraulic system that is not only extremely powerful, but is also exceptionally accurate - guaranteeing a consistent manufacturing quality and resulting in the very best product that can be made.

Warranty

Many manufacturers guarantee their swaybar for only one or two years, and oftentimes their warranty is voided if the vehicle is raced or subjected to untold abuse that the vehicle may be subjected to. And others do not even mention any warranty provisions - instead they hope and pray that nothing ever happens to their products. They purposely limit their liability because they do not have the confidence in their finished product because they are fully aware that it can be manufactured to a higher quality level.

At Steeda, we are so confident that our swaybars are manufactured to the highest quality levels that we put a free unconditional lifetime guarantee on every one we manufacture. Our warranty is further reinforced by our ISO 9001-2008 manufacturing process that strategically monitors all phases of manufacturing - ensuring that the quality level of the finished product is never compromised. With a lifetime warranty and strict ISO 9001-2008 certified standards, we have complete confidence in our products so you can also can have complete confidence in what you have purchased. Advantage: Steeda .

The final word When Ford performance enthusiasts discuss chassis dynamics, it will not take long for the name Steeda Autosports to come into the conversation - and with very good reason. If you want the ultimate in suspension upgrades for the street, track, or strip - look no further than Steeda Autosports. We are the Number One in Ford performance parts and vehicles with our parts have won more races and set more track records than all of our competitors combined. At Steeda Autosports, we take the development and refinement of a vehicle's suspension system very seriously and have spent countless engineering and development hours to bring to market the very best swaybars available today. 'Track Tested and Street Smart', our swaybars are equally at home on your street driven vehicle or on the racetrack, they simply have no equal in the industry today. Designed and manufactured exclusively by Steeda Autosports in the USA under strict ISO 9001-2008 standards, they withstand the rigors of high performance racing and yet exhibit excellent NVH characteristics, so you get the performance and handling benefits you want without degrading your ride quality.

Steeda - Speed Matters